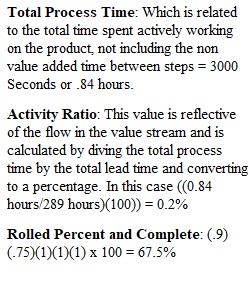

Q Overview A core tool in Operational Excellence is Value Stream Mapping. This tool helps stakeholders visualize complex work systems (including material and information flows) and address disconnects, redundancies, and gaps in how work gets done between the beginning and end of a value stream or end-to-end process. • The primary type of value stream is one in which a product or service is requested by, and delivered to, an external customer. Examples include request to receipt, order to delivery, and quote to cash. • Other value streams which support the delivery of value are called value-enabling or support value streams. Examples include recruiting, onboarding, IT support, and annual budgeting. Since it is nearly always a mistake to initiate changes without have a clear picture of how the system is currently functioning, we are beginning our Course Project with the creation and analysis of a Value Stream Map. Instructions For this assignment, select a value stream in your organization that can benefit from analysis and improvement. As noted previously, the value stream (or end-to-end process) selected does not need to be overly large or complex. Select something which has the potential for meaningful improvement, but which is manageable within the scope of this assignment. 1) Develop a current state Value Stream Map of your selected value stream. Show the customer demand rate (or Takt), information flow, work flow, and summary timeline on the map. 2) Document key metrics for each process block: • Process Time (PT) • Lead Time (LT) • Percent Complete and Accurate (%C&A) • Any other appropriate metrics, such as number of operators, changeover time or setup time, batch size, and % uptime. 3) Calculate the current state summary metrics: • Total lead time (Total LT) • Total process time (Total PT) • Activity Ratio (AR) • Rolled Percent Complete and Accurate (Rolled %C&A) © Strayer University. All Rights Reserved. This document contains Strayer University confidential and proprietary information and may not be copied, further distributed, or otherwise disclosed, in whole or in part, without the expressed written permission of Strayer University. This document is subject to change based on the needs of the class. 4) Describe the current state of the value stream and highlight any performance deficiencies and challenges, such as delays, excessive WIP, bottlenecks, capacity and workload imbalances, rework, poor quality yields, long lead times, and other operational issues. Submission Requirements Your work may be submitted in either Word or PowerPoint. • Since you will need to include a diagram to map the value stream for #1, you should select whatever software you are most comfortable working with. The Value Stream Map can easily be created in PowerPoint (see the symbols and template provided by the instructor), or neatly drawn by hand. You may also use software such as Visio. In all cases, please scan or convert your map to a PDF or JPG, and paste it into Word or PPT before submitting. • For #2, the information for each process block should be on the value stream map. For #3, it can be on the map or in tabular form. Show how the summary metrics are calculated. Keep your written answers brief and to the point. Accuracy is what matters. This should take no more than one page. There are no additional points for overly elaborate responses. • For #4, a thorough response with specifics should take no more than one page. As you discuss improvement opportunities, mention and make specific reference to the Value Stream Map, including names of process blocks and performance metrics.

View Related Questions